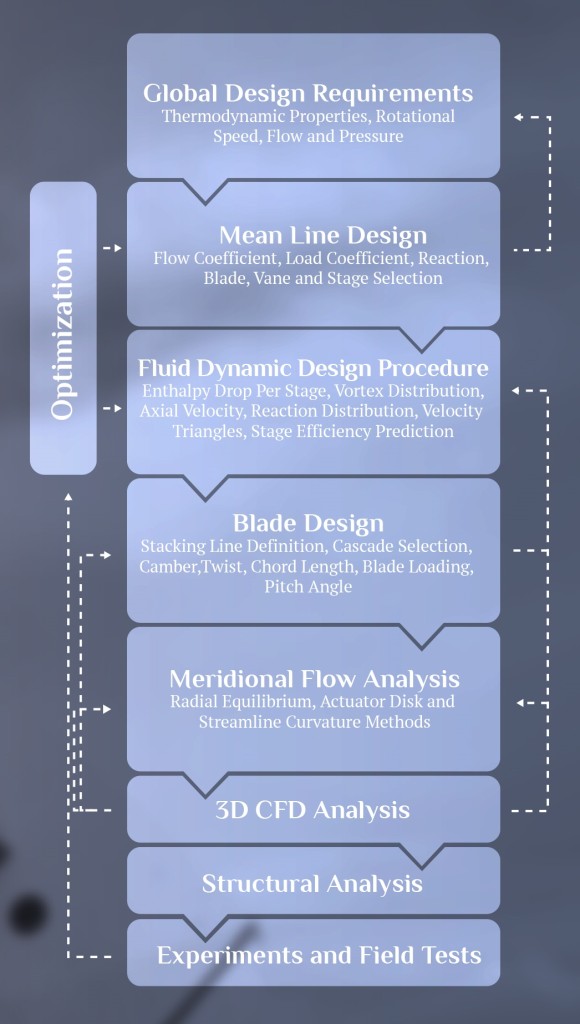

Air movement fan design is a specialized process requiring knowledge of sub-sonic aerodynamics and structural mechanical design. AGS Consulting, LLC has developed a suite of design tools that facilitate the design and optimization of new air movement fan geometry.

Starting with a target pressure and flow operating envelope, AGS Consulting, LLC use an in-house mean-line one-dimensional design tool to facilitate definition of overall fan geometer. A fluid flow design procedure is then embedded within a second design tool that facilitates the identification of blade or impeller geometry capable of achieving the target pressure and flow operating envelope. The output of this design tool is then used as input to a third design tool that is used to define blade or impeller geometry. Once blade or impeller geometry is defined, a meridional flow analysis tool is then used to predict fan performance. Output of the meridional flow analysis tool is in the same format as the data that would be measured if the fan had been built and tested in a laboratory, characterizing air performance of the new design.

Once fan geometry has been defined and its performance characteristics predicted AGS Consulting, LLC can undertake a full three-dimensional computational fluid dynamic (CFD) simulation of the flow-field though the fan. The simulation results facilitate the identification of flow-field features that reduce fan efficiency, and therefore provide an insight into changes in geometry that may minimize of eliminate undesirable flow-field features. In so doing the three-dimensional computational fluid dynamic analysis provides a form of feedback that AGS Consulting, LLC then use to refine the fan blade or impeller design.

The development of new fan aerodynamic designs must be undertaken within the context of allowable structural limits. AGS Consulting, LLC therefore undertake a structural analysis of each aerodynamic design, optimizing the mechanical design to ensure structural limits are respected. The resulting final design is therefore both aerodynamically optimized and structurally optimized to ensure that mechanical limits are not inadvertently overpassed.

Following aerodynamic and structural optimization, AGS Consulting, LLC can undertake the rapid prototyping of new blade or impeller designs, followed by their laboratory testing in accordance with the requirements of AMCA 210.