AGS Consulting, LLC specializes in the application of aerospace design methods to the design of commercial and industrial fans. Historically fan designers have favored empirical design techniques. However, current and forthcoming legislation mandating minimum allowable fan efficiency has resulted in these techniques reaching the limit of their capability.

By systematically developing and applying aerospace derived design techniques, AGS Consulting, LLC has created an in-house design tool that facilitates the development of axial, mixed flow and centrifugal fan blade or impeller geometry. AGS Consulting, LLC compliments its design capability with a unique virtual laboratory that is used to predict performance of the resulting geometry before building a physical prototype. The virtual laboratory results are then used in combination with physical laboratory results to expedite AMCA air performance certification.

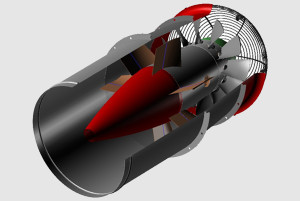

AGS Consulting, LLC was asked to analyze performance of the fan embedded within a snow gun. These snow guns are used in skiing resort to make snow during the night to help ensure ski slopes remain open when natural snowfall is not alone enough. The design of fans intended for application in snow guns is made challenging as a consequence of the critical velocity needed to ensure that water injected into the exhaust of the snow gun turns to snow. Too slow, and the snow is water logged. Too fast, and the snow is so fine that it drifts away, rather than settling on the ski slope.

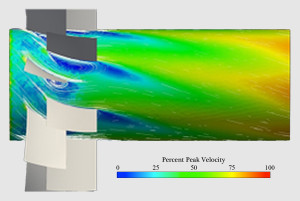

AGS Consulting, LLC was able to identify regions of separated flow though the rotating stage of the snow gun fan. This insight into the flow-field features responsible for asymmetry of the flow-field at the fan exhaust facilitated the origination of a new approach to blade design that was used to both reduce the variation in velocity from the snow gun and reduce the blade number from twelve to six. In so doing AGS Consulting, LLC was able to both improve snow quality and reducing snow gun cost.

The snow gun incorporating the redesigned fan is widely used in Italian ski resorts, consistently producing quality snow. The ability to reliably manufacture quality snow has helped to extend the skiing season. The more uniform velocity in the fan exhaust helps operators to select optimum water flow-rate and droplet size, which in turn facilitates the manufacture of quality snow even when night time temperatures are higher than ideal.