The performance of fans intended for commercial and industrial application may be established through a performance test conducted in accordance with the requirements of the standard AMCA 210 Laboratory Methods of Testing Fans for Certified Aerodynamic Performance Rating. The standard defines allowable test set-up configurations that may be used when testing fans. However, the standard does not provide architectural drawings for each test configuration and consequently every test system is unique.

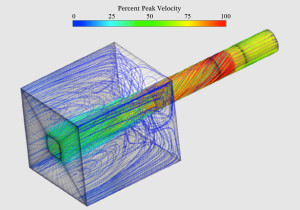

The consequence of each test system being unique has been evaluated by AMCA though round robin tests during which the same fans were tested in different test systems. Particularly for tube axial fans, the difference from test system to test system resulted in significant variation in measured fan performance. In response AGS Consulting, LLC has developed a virtual laboratory to create accurate three dimensional models of fan manufactures actual test system geometry. The virtual laboratory utilities the actuator disc method to simulate the presence of a fan in the test system, with a fully three-dimensional model of the test system ducts and chamber.

By modelling the actual geometry of a test system, actual recirculating flows within the test system chamber are also modelled. Although velocities in the test system chamber are low compared to those within the test system ducts, they are still high enough to have a measureable impact on fan performance. Consequently, the AGS Consulting, LLC virtual laboratory is able to compensate for the effect of actual test system chamber geometry and in so doing better predict measured fan performance.

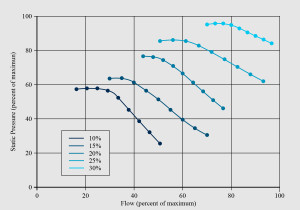

In the example to the right performance of an axial fan was measured and predicted with a blade angle of 10 degrees. The results match within the tolerances allowable within AMCA 210. Fan performance was then predicted at 15, 20, 25 and 30 degrees using the virtual laboratory. The virtual laboratory therefore has the potential to compliment a manufacturers laboratory, increasing a manufactures ability to generate fan performance by an order of magnitude. Although the virtual laboratory is not intended to replace laboratory testing, this increase in productivity significantly reduces the time taken to bring new products to market.